The Chester County Career Center's article about OWI's Robotic Arm Edge.

With permission- Mr. Gail R. Hirschy

Pre-Engineering, Mechatronics Instructor

CHESTER COUNTY CAREER CENTER, CHESTER, SOUTH CAROLINA INTEGRATES THE OWI, INC.�S ROBOTIC ARM EDGE INTO MECHATRONICS CURRICULUM

At the Chester County Career Center in Chester, South Carolina a Mechatronics course is offered to students under ahigh school Pre-Engineering program. One of the requirements for a capstone project is for high school seniors to design, assemble, program and troubleshoot an industrial robotic automated assembly line and to be highly skilled in the area of robotic automation. Without constructing an actual robot in their prerequisite courses, students have found the troubleshooting aspect of the robot quite difficult, especially when working with the various joints and the movements of the joints. The robots used on the simulated assembly line are used strictly for programming due to the need for accuracy and working with close tolerances. Constant disassembling and reassembling the robotic arms on the simulated automated assembly line would cause the accuracy and tolerances to lose their calibration. Students can remember the various joints and parts of a robot when they have the opportunity to actually construct and have hands-on activities with an actual robotic arm.

For the past several years, the Career Center has been researching various educational robots on the market that could be used in the prerequisite course to teach the students about the various parts and construction of an industrial robotic arm. OWI, Inc. offers the best robotic arm on the market and the robotic arm is very representative of the robotic arms used in industry. Learning can take place on the OWI Robotic Arm Edge and can be transferred very easily to the real-world robotic arm. The OWI, Inc. Robotic Arm Edge is a robotic arm that is identical to the robots that the Chester County Career Center uses in the classroom on the industrial robotic automated assembly line. South Carolina is the home to BMW Automotive Manufacturing, Boeing Aircraft, Michelin Tire, Bosch Industries and other major manufacturing industries that require highly skilled employees trained in robotic automation. The OWI, Inc. Robotic Arm Edge is the perfect solution for a learning tool for understanding the inner workings of a robot that is identical in nature to the robots being used in industry today. We, at the Chester County Career Center in South Carolina would like to thank OWI, Inc. for providing a solution to our missing link in training students to work for highly skilled robotic automated industries. The OWI, Inc. Robotic Arm Edge will be put to excellent use as students will advance from the Robotic Arm Edge to the automated robotic simulated assembly line to an actual industrial robot to on-the-job training and a career.

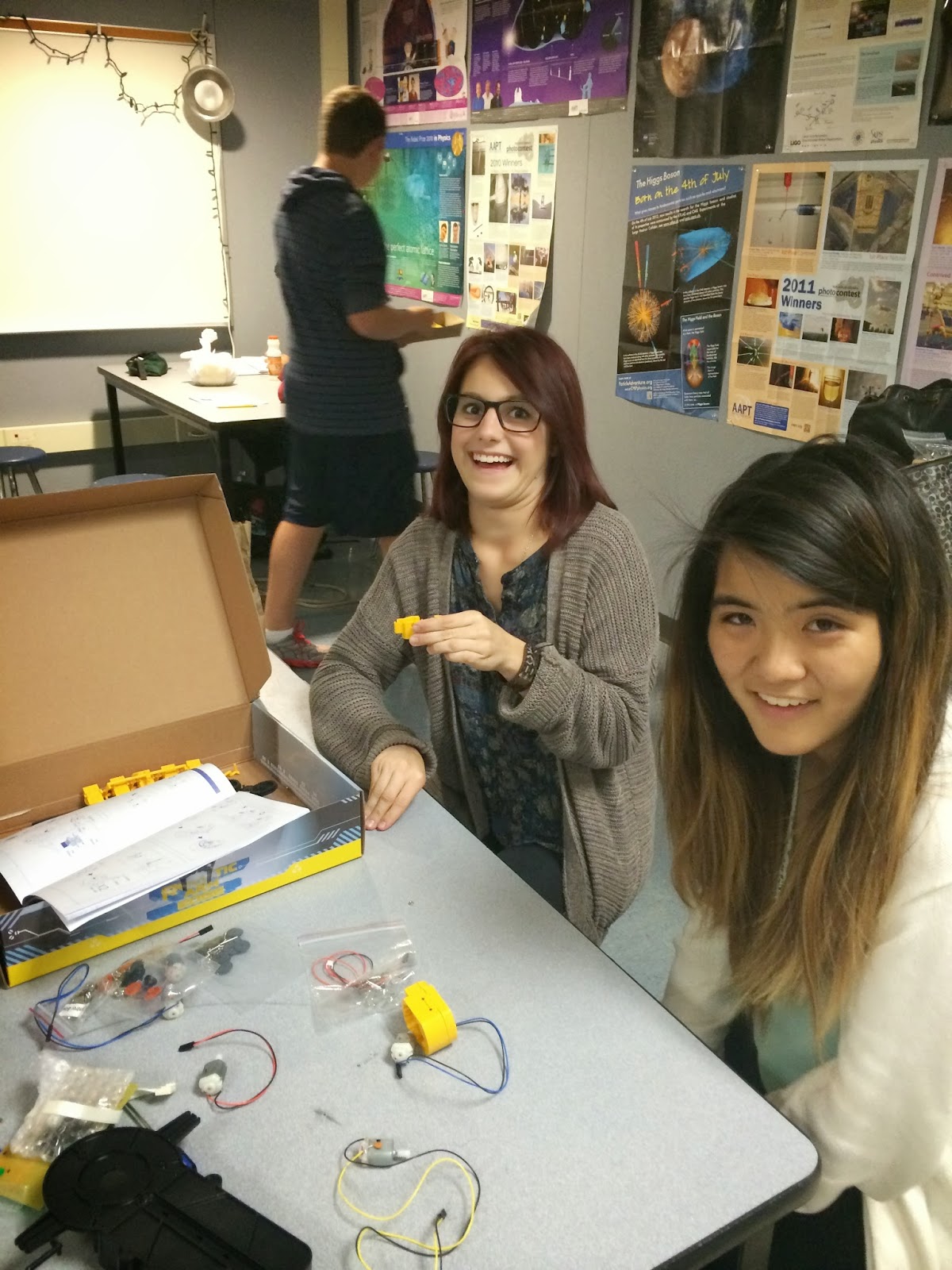

Mechatronics 1 students will be provided with an OWI Robotic Arm Edge when entering the classroom for the first time. The students will be required to assemble the arm, label each joint, describe the rotation of each joint, be familiar with all parts on the robotic arm and all students will be required to operate the robotic arm to perfection. The student will also program the robotic arm using the Images Serial PC USB Interface. The instructor will also provide problems for the robotic arm that the students must troubleshoot and fix in order for the robotic arm to function properly.

Upon completion of the Robotic Arm Edge activity, the students will then proceed to programming a single robot on the simulated industrial assembly line. The students will be required to program not only the robot but also the electropneumatic section of the assembly line along with a conveyor system and a quality control system. Learning about the robotic automated assembly line will involve a real-world problem that requires the students to design, assemble, wire, program and troubleshoot the entire assembly line. The completed project must be completed within a ten hour time frame in order to keep a company�s non-production time to a very small amount of time. Transferring knowledge from the Robotic Arm Edge to the simulated automated assembly line is very important for the students.

When the second section of the required project is completed the students will now start adding various robotic stations into the automated assembly line. The entire assembly line will require three robots to produce one product and for a fourth robot to check for final product quality. All four robotic stations must be synchronized to perform an operation on the product without allowing the remaining three robots to become idle during production.

The knowledge that has now been gained from the robotic arm activity and the simulated robotic automated industrial assembly line activity can now be transferred to the ABB IRD 140 actual life size robot which was donated to the Chester County Career Center by one of the major industries in South Carolina. The students will now design, test and build a working end effector for the ABB robot. Once the end effector has been installed on the ABB robot, the students will program the robot to use the end effector in a real-world situation. This end effector can be a gripper to move product, a welding arm to weld parts, a paint nozzle, or any other device the students choose to invent. The ABB robot must have the end effector installed, must be programmed, must operate flawlwessly and must be able to operate continuously.

Robotics is a very comprehensive and a very important part of the overall Mechatronics curriculum. Robotics is only one of the six areas the students will study in order to become certified and a completer in Mechatronics. The World needs highly skilled and highly trained workers for the industrial workforce. The Chester County Career Center in Chester, South Carolina is very appreciative of OWI, Inc. for playing a very vital role in helping us to educate students to become highly skilled workers for the future of the World by providing us with the Robotic Arm Edge.

Comments

Post a Comment